Today’s ultra-competitive industrial climate has manufacturers looking for ways to become more agile and adapt quickly to rapidly changing markets and an increasingly diverse range of customer demands. Digital transformation is one approach that many enterprises are using to become more agile. To digitally transform their facilities, they are turning to smart technologies such as Industrial Internet of Things (IIoT), digital twin/thread, artificial intelligence, machine learning, cloud computing, mobility, analytics, and so much more. For many, the ideal facility is a place where operations, IT, supply chain and customers all coexist in a collaborative and information-sharing environment that breeds efficiency and reliability.

The road to a smarter, more modern facility isn’t easy, however. For many manufacturers, a substantial gap exists between their current state and what is required to begin adopting these technologies. Recognizing how smart technologies enable bottom-line value is a good first step toward bridging the gap, but recognition alone isn’t sufficient to power a company’s effort to reach ‘elite’ status. Many manufacturers struggle against an outdated and poorly designed control system infrastructure that limits their ability to adopt these important enabling technologies.

Before success can be realized, manufacturers must address these legacy restrictions and develop a capable foundation that supports new and emerging technologies. They can also scrutinize their operations and see where smart technologies could fit into their existing infrastructure while continuing to support their business needs and process requirements. Ultimately, the road to a smart factory is a journey that requires innovation, an upfront plan and a solid implementation strategy that is based on a holistic design approach with an eye toward modularity, agility, and ultimate sustainability.

A Time to Innovate

Tackling an automation hardware and software project of any magnitude is not for the faint of heart. Key stakeholders must decide whether to replace systems piecemeal or start over completely with all new systems. No matter the chosen path, a qualified team using a standards-based approach is critical to achieve consistency and meet companywide functionality requirements.

As the brain of the production facility, the process control system is critical to business operations and, as such, is rarely altered. A business-sanctioned modernization project is the ideal opportunity to evaluate current operations and leverage smart technologies not to replicate these critical systems – but innovate instead.

Replicating existing issues will reduce the flexibility of the new control system from the very outset and will continue to limit its potential over its lifespan. Manufacturers could end up back where they started – with the same functionality simply being implemented in different ways, creating maintenance challenges down the road.

This is not to say that manufacturers should outright dismiss the value of their existing legacy systems. They must preserve and leverage the years of intellectual property configured into existing systems. All their positive aspects should be captured and combined with the new technologies being implemented.

Incorporating the latest control functionality – developing effective human-machine interfaces (HMIs), alarm management, compliant safety systems, the latest cybersecurity defenses and other valuable technologies – will enhance profitability. The key to success is to identify what new technologies will provide the most benefit and return on investment (ROI) for a company’s unique situation.

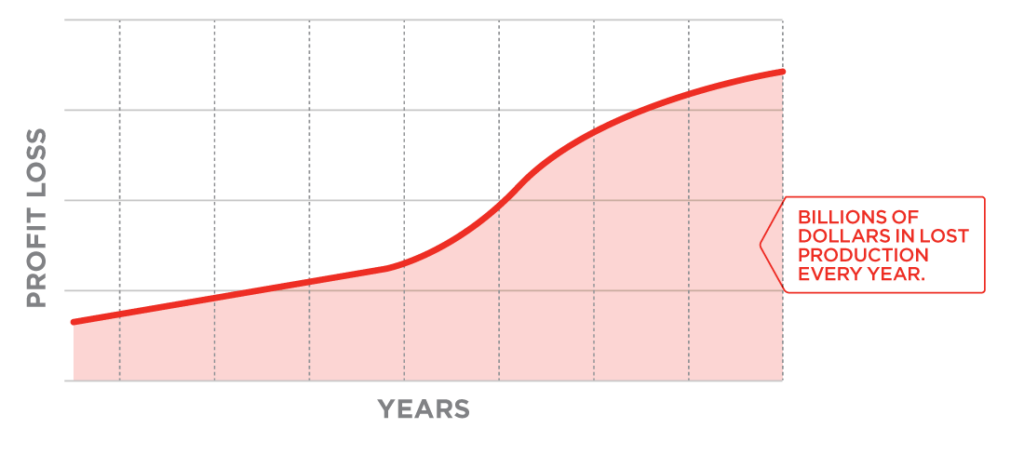

For instance, legacy HMIs are an area that has been consistently identified as a problem for operators. Unclear and ineffective graphics, along with a poorly defined alarm system lacking proper prioritization, improperly set alarm points and ineffective annunciation lead to unplanned downtime and billions of dollars in lost production every year.

Facilities that deal with these real-world issues could benefit from a properly functioning alarm-management system. A modern high-performance HMI can help operators respond more quickly to problems by clearly distinguishing between low-priority, high-priority or critical alarms to mitigate abnormal situations before production is impacted.

These projects are inherently complex. Internal resources have limited bandwidth, so engaging an automation solutions provider with expertise in planning, design and implementation can move a project forward with reduced risk and greater success. Depending on size, the project scope must be parsed into multiple projects, where each has its own schedule that includes:

- The current and subsequent front-end loading (FEL) process

- Design

- Engineering

- Testing

- Installation

- Startup & commissioning

A trusted third-party automation solutions provider can help evaluate the overall situation and create a well-defined project scope and framework that aligns with the company’s business goals. It all starts with a solid plan.

Plan Early

Front-end loading/front-end engineering (FEL/FEED) – A wise and necessary first step for a modernization project is the FEL/FEED effort, which makes sure an execution plan and schedule are in place to keep the project on time and on budget. Each phase of the FEL process (FEL1>FEL2>FEL3) – from conceptual “go/no-go” for the project to capital planning estimates to refining the details that justify funding – helps reduce implementation risk for cost, schedule and system performance. The FEL process also helps determine the best control system platform to meet the business needs, and provides accurate, justifiable cost estimates to navigate the CapEx funding process and secure stakeholder support.

In addition to the technical aspects of an FEL, companies can benefit from an upfront capital expense (CapEx) evaluation and iterative implementation approach to balance improvement efforts with cash flow constraints. When strategic improvement goals are bound to a piecewise project execution method, however, it is important not to lose sight of desired long-term outcomes. Often, too much emphasis is placed on traditional objectives like simpler, cheaper and faster – evaluated on a per-project basis. This myopic approach can negatively impact the long-term goals of a broader modernization effort.

Project execution plan (PEP) – Preparing and planning for startup and commissioning early in the process helps synchronize construction activities, which is important to identify any potential equipment issues and minimize risk for a more successful project outcome. Before creating a plan, personnel should identify and define any potential risks (for example, downtime, network traffic levels, data integrity, operator graphics and alarms, cybersecurity and more) and determine how to mitigate them.

A detailed PEP for both the engineering and the installation of the new system includes reverse-engineering the functionality of the legacy system to make sure that none of the functionality is left behind, as well as how the new system will be cutover – hot or outage. A PEP is also the time to gather information regarding piping and instrumentation diagrams (P&IDs), instrument specifications, single line diagrams, loop sheets, and other pertinent design documents. It includes defined roles and responsibilities, risk matrix, quality plan, testing plan, training plan, resource-loaded schedule and other appropriate items – all of which are important for effective execution.

Holding regular project team meetings and following a proper communication plan will help keep everyone in the loop and performing as planned. Document control will verify that documentation is properly managed and updated so that the latest revisions are readily available and easily retrieved by the people using them. These best practices will greatly improve efficiency when construction and commissioning activities begin.

Overall, proper upfront planning requires a holistic review of the entire facility’s operations. Be sure to discuss all companywide factors before developing a migration plan while there is still the greatest flexibility to deal with them. It can’t be emphasized enough – early effort spent on good planning and definition pays for itself many times over.

Smart Data Needs Flexible Networks

Another area that requires attention early in the upfront planning process are networks. Any attempt to modernize a company’s operational proficiency must start with a thorough evaluation of its network infrastructure.

The integrated technologies underpinning the smart factory run on data. Smart technologies are essential tools in capturing and analyzing data and turning it into intelligence for industrial personnel to make data-driven decisions in real time. Recognizing that data is the lifeblood of the smart factory, and that data runs through networks, don’t overestimate the importance of a capable and efficient network to operational success.

Many facilities run on networks that evolved, rather than resulted from thoughtful planning. Those networks often started small and grew as needed to support new operations or system functionality. The unplanned sprawl that results from this sort of evolutionary growth produces networks that are sluggish, cumbersome to maintain and often lack proper security features.

Think of a network infrastructure as the central nervous system of the body, connecting all parts together in a way that enables them to function as a unit. Without it, facilities have a collection of disjointed parts. Like the nervous system, a proper networking infrastructure operates efficiently and homogeneously – even when different mechanisms are employed. Like the body uses both electrical and chemical messages for passing information, a network will use multiple protocols to achieve the best fit of features to function. Replacing outdated or hard-to-support protocols with mainstream ones will minimize incompatibility problems while shoring up the enterprise network.

Design and Develop for Agility

A good holistic design approach is foundational for addressing the long-term needs of a smart factory. Success results from production processes and systems that are equally agile and can adapt quickly to change – not ones hindered by cumbersome designs and slow change management procedures.

Legacy control systems were designed as standalone solutions, without standardization of method or function. When considered altogether, these systems often have holes or overlap in the functionality required for them to interoperate efficiently. To act as a proper foundation for the smart factory, these systems would need to have been constructed in a cohesive manner from a primary plan or template – which is rarely the case.

Depending on a facility’s infrastructure, the approach to the redesign effort varies, but the best design blends appropriate quantities of tried-and-true methods with value-adding modern technologies. Modular designs support upgrades using standards-based products and software. Object-oriented design, for example, is one of those more recent technologies that can greatly improve the speed and agility of project implementation, while establishing a consistent, flexible and capable platform for implementing any of the smart factory’s functional needs.

Execution and Implementation

When it comes time for the execution and implementation phase of an automation project, qualified personnel must execute rigorous testing and commissioning procedures to achieve safe and efficient startup. A qualified team will use the documentation gathered from the PEP to create dynamic test plans and document procedures, such as loop checks, control system hot cutovers, and more. These detailed plans serve as the execution blueprint for each pre-commissioning assessment and are used to verify that each device performs both individually and systematically as intended before startup.

Shortcuts here will inevitably lead to operational problems, costing many times the minimal savings from reduced commissioning time. Take the time to create thorough procedures with input from subject matter experts who have experience with automation and to follow the procedures carefully using personnel who have done it successfully before.

The Path Forward: Sustain and Improve

Much emphasis is placed on a solid plan and a holistic design, as these important elements greatly impact the success of implementing and sustaining a process control system. Thedetails of the execution plan ultimately determine the timeless viability of a new automation solution based on that initial design. If planned from the start of the project, continuous improvement initiatives can help manufacturers optimize processes and increase operational safety and efficiency, giving them an ongoing competitive advantage.

It is important to establish standards and good automation engineering best practices to make sure that the new automation system is designed and configured in a way that meets your facility’s requirements while being maintainable over the long term. A good design makes sure the automation solution can accommodate desired new features, functions and technologies. These systems are likely to be around for decades, and the chance that changes and improvements will be needed and desired during a system’s lifetime is pretty much a sure thing.

To this end, as manufacturers plan, develop and build their smart factory, they must also consider new approaches, such as setting up secure remote infrastructures and establishing remote application support capabilities to optimize, maintain, and sustain their facilities.

Where remote access capabilities are required, legacy systems present a challenge as hardware and software support, security updates and software fixes for older releases become obsolete. Manufacturing personnel must safeguard their IP with critical updates, reboots and patches for system security and reliability. They can develop remote management strategies where they leverage smart technologies, mobile devices, remote access connectivity and communications tools to make sure critical infrastructures remain up and running efficiently.

Reducing the time in-house personnel must perform or be trained on critical automation tasks can realize a cost savings. Consider outsourcing remote management and preventative maintenance services to help ease the workload for personnel having to perform various critical tasks. These tasks include, but are not limited to, incident management, system backup and recovery, data analysis and retrieval, software updates and patches, real-time monitoring of software and systems, machine learning, predictive analytics, IT/OT hardware refresh, online automation and system programming edits.

Regardless of a facility’s size, the road to a smart factory is navigable if there’s a clear path outlined at the beginning. A modernization project’s successful outcome depends heavily on a disciplined approach and holistic plan from initial design concept through implementation and startup. Long-term goals to sustain and continuously improve the new smart factory further makes sure that systems are flexible and agile for ongoing competitive success.

Smart manufacturing technologies are also transforming other critical strategies and address The Problems Smart Manufacturing Solves for the C-Suite.

ABOUT THE AUTHORS

Richard Slaugenhaupt is a senior consultant at Rockwell Automation, a leading automation solutions provider. He has been working in manufacturing automation for more than 40 years, serving both small and large clients in many different industries.

Lynn Njaa is a senior proposal consultant at Rockwell Automation. In her role, Lynn leads team efforts to provide consulting and other front-end engineering services.