Industry has numerous articles about PID (proportional, integral, derivative) controller loop tuning and its various approaches. From complex mathematical algorithms to various tuning techniques, loop tuning often presents itself as a black box that requires a certain mathematical artistry to open. One way to open this box is to ask, “What kind of process is being controlled?” To answer this question, keep in mind that proportional relates to size while integral relates to time. We will briefly talk about derivative at the end.

Accumulating Processes

Most processes can be categorized as either accumulating or non-accumulating. By accumulating, we mean that the process is collecting or holding material or energy, such as most levels and some temperatures and pressures. A non-accumulating process would be most flows, where a change in the control device almost instantly translates to a change in the process measurement. Let’s first look at accumulating processes and determine how to tune those.

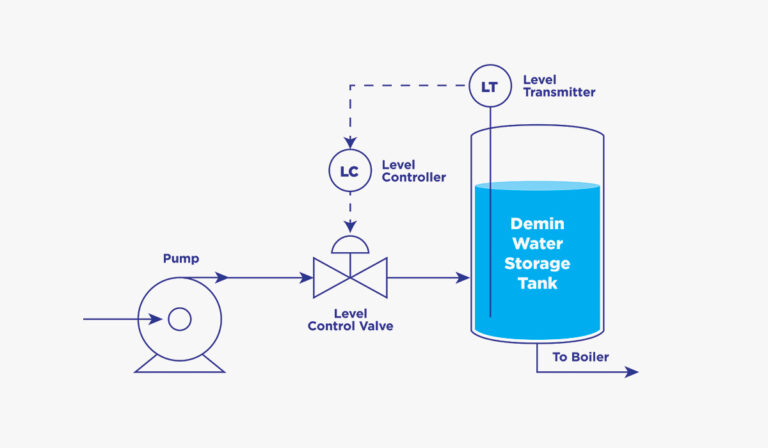

Let’s say the tank in figure 1 holds 10,000 gallons of demineralized water and that the maximum feed rate is 1,000 gallons per minute. It’s not hard to determine it would take 5 minutes for the tank to fill halfway. Obviously, the larger the vessel and/or the smaller the feed rate increases the time to accumulate the level.

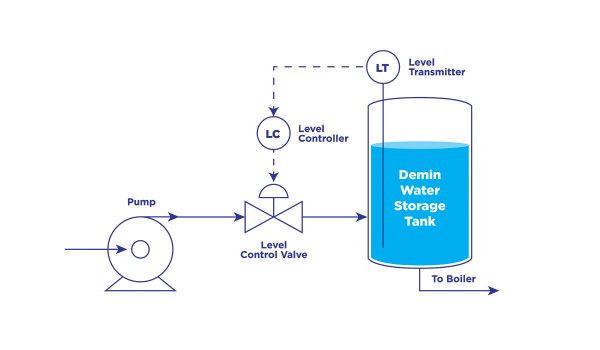

Accumulation can also be thought of in the mathematical term of integration where we calculate the area under a curve (figure 2). In this view, the area is relative to the mass accumulated, and the integral time is relative to the accumulation time.

Piecing all this together tells us that since the accumulation time for a level tends to be long, then the integral time should also be long. Thus, the time it takes to fill or empty a level is relative to the integral period. Assuming we are using minutes per reset, we might look at 5 minutes for a starting point for the integral time of our tank.

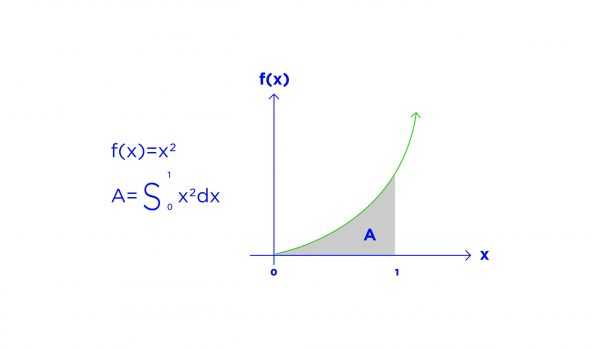

Now let’s look at proportional terms. Clearly, if the tank fills or drains suddenly, we want the controller to react even to the point of moving the output to its limits. If we imagine the proportional term like a seesaw where the fulcrum moves changing the proportion of the weight needed on each end to balance, we can start to determine the kind of proportional gain required.

In figure 3, “m” might represent the desired output to the control valve while “n” represents the error from the desired setpoint. The ratio “a/b” would then represent the proportional gain. Using some real numbers, let’s say the desired setpoint is 50% level. Let’s say the measurement is 25% creating an error of 25%. Now, we want our control valve to be at maximum output at that point. The gain then becomes 100/25 or 4.

In most cases when looking at a level, the proportional gain should be 1 or greater. In that way, we move the output at least at a 1-to-1 proportion to the error so that the valve is at the extremes when the vessel is near full or near empty. Imagine that normally the controller sits with the valve halfway open, and we are trying to maintain the level at half full or 50%. To get the valve fully opened or fully closed when the tank goes empty or full means putting the proportional gain at least at 1. In other words, we want full travel of the valve over the range of the level using proportion.

So now we’ve created a rule of thumb for P & I terms regarding our level. P (proportional gain) needs to be greater than 1, in this case we decided on 4. I (integral time) needs to be long, in minutes not seconds. In this case, we decide on 5 minutes based on fill time. Note there are ALWAYS exceptions to any rule, but this gives us a decent starting point.

Non-Accumulating Processes

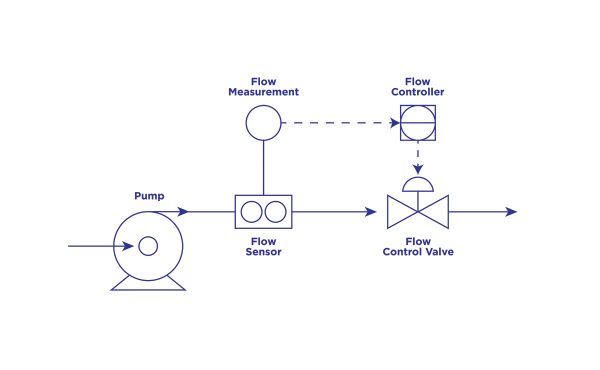

Now let’s look at a non-accumulation process, such as flow, so we can see the difference in tuning. When we change the output to the control valve, we get an immediate change in the process variable. So, there is little accumulation. Where it takes a lot of time to accumulate materials in a level, it takes almost no time for the process to react in a flow.

In figure 4, we can determine the time it takes for the material to flow down the line from the sensor to the control valve. In most cases, we are talking a matter of a few seconds. From this determination, we can conclude the integral time is fast, let’s say 5 seconds.

Let’s look at proportional action. For a level, it took a large change in valve position to make a small change in the level. For a flow, we see that a large change would immediately move the flow rate to an extreme. So, we know we want a smaller ratio (think back to our seesaw), almost certainly numbers less than 1.

Key Tuning Questions

Now, the questions we really need to ask in order to tune our process are:

How large is it?

- Size – its largeness gives us an idea where our proportional term stands.

How long does it take?

- Time – the period it takes to move from one value to another gives us an idea where our integral time should be.

Keeping size and time in mind, we can take a quick look at other types of process conditions and controls.

Hydraulic Pressure – Hydraulic pressure acts much like a flow. As soon as we adjust the control output, we see a rapid change in pressure. So, like most flows we would expect short integral times and small proportional gains. Example: P=0.5; I=20s.

Vapor Pressure – Since gas is compressible, it has an accumulating property. This is especially true when we are talking about head pressures in a vessel. We can expect larger proportional terms and longer integral times. Example: P=2; I=120s.

Temperatures – This is where most people struggle as it’s hard to figure out how long it takes to get a BTU through a brick. Actually, BTUs and where they are going is key here. If we are generating BTUs in combustion, we can see changes rapidly, whereas if we are transferring heat it takes time. By considering the heat capacity – the time it takes to generate and move the BTUs – we can get some idea of what the tuning might look like.

For example, a tray temperature in a distillation column would take significant time to get there, but once it got there, it might change quickly. Making a step change in the control output can give us an idea of what the time period is and help us pick an integral time. The amplitude ratio between the change in output and the change in temperature can give us some idea on proportional gain.

Again, we just want to know the size (proportion of output to process change) and how long it takes (integral time).

Derivative / Rate of Change

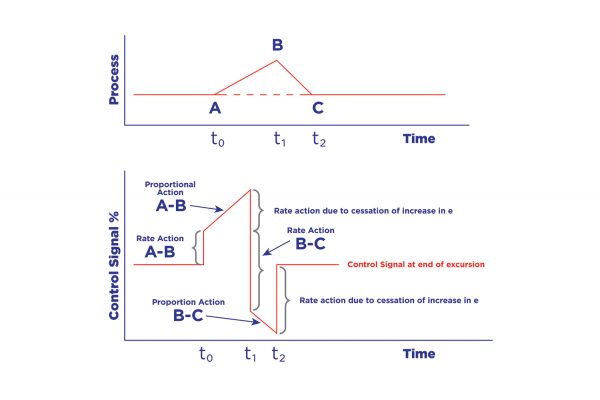

Derivative action – also known as rate of change – should be rarely used. Its best use is for “excursion control.” This is when a process has some force within it that causes a rapid change. For example, the kickoff of many reactions will cause a sudden temperature rise followed by a rapid fall in temperature. Figure 5 illustrates such an excursion.

While integration is about accumulation and finding the area under a curve, derivative can be looked at as the rate of change or the slope of a curve.

Fine Tuning

In summary, proportional is all about size, integral is about how long it takes, and derivative is about sudden change. Understanding the basic behavior of your process can go a long way to deciding where to start tuning-wise. After that, we perform some fine tuning by making changes to the setpoint and some adjustments to get the kind of curve preferred, most typically quarter wave decay where each successive swing is 25% of the previous.