New upgrades or expansion projects don’t have to be late or bust the budget. With good planning and strong management, they can finish on time—or even early.

This simple fact runs contrary to experience for many companies. Process facility projects can be very challenging, from a simple unit upgrade to a new greenfield production complex. Process control and automation systems are invariably involved in any type of upgrade or addition, sometimes as the primary item, or an element of a larger project.

Whether small or large, construction projects are complex and carry a high level of risk:

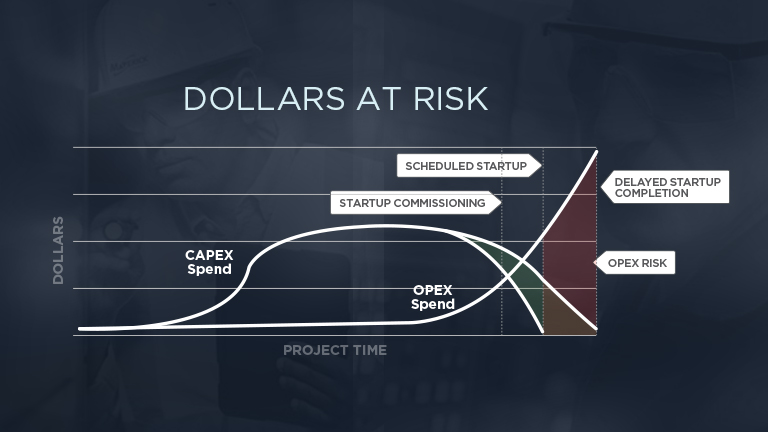

- Cost overruns involving capital (CAPEX) and operating (OPEX) expense budgets add to pressure.

- Schedule delays increase CAPEX costs and delay expected cash flow from new production capabilities.

- Companies often underestimate the true cost of a delayed startup because they miss counting the lost income from production beginning behind schedule (Figure 1).

- Some improvement projects are ultimately considered failures because they do not deliver expected production levels.

There is no shortage of horror stories from companies launching projects with great expectations, only to see their costs balloon and schedules go out the window. A company considering such a project has to ask, “Are there characteristics of underperforming projects we might be able to avoid?”

Here are some common mistakes:

- Inadequate planning or, more accurately, the wrong kind of planning:

Many companies understand the importance of planning, but simply don’t know how or don’t have the bandwidth to deal with so many critical elements. - Planning too late in the schedule:

Many companies assign planning to people with too much to do already. When more pressing issues consume their time, critical steps do not happen early enough. - Bringing too few resources:

How many of your people have time to dedicate to an upgrade project? Do the ones with available time have the right skills? Does anyone have relevant experience? - Too few people recognize problems developing:

An inexperienced person trying to manage construction may not be able to tell when a minor problem threatens to turn into a big one.

The unfortunate results of underperforming projects are easy to see: production starts up late, costs are too high, the process doesn’t deliver the performance the owner expected, and documentation is inaccurate or incomplete. The project is viewed as a failure along with the people who tried to make it happen—unfair as such a judgment might be.

It Doesn’t Have to Be That Way

Underperforming projects are a major problem, yet they can be prevented. Projects can be managed skillfully so they get completed on time, on budget and in line with performance expectations.

Planning done early enough and implemented by people who know how to drive projects makes the difference. Many companies underestimate the positive impact the right team can have in guiding a project. This group should include a variety of people, both employees and contractors, from all functional areas and with representation from all construction trades that will be involved.

Driving Accountability

Eventually, a project moves from planning to construction. It may involve bulldozers or less visible improvements to automation infrastructure. Either way, construction and related project activities must be actively managed to keep things on course and on schedule. Without people who can dive in and drive each element, the project can quickly fall behind.

An effective project manager breaks the linear construction timeline into subsections so each can be managed and tested along the way. Executing multiple steps simultaneously in parallel makes the schedule collapse on itself, reducing the overall project time.

Testing During Construction

Keeping aggressive project schedules on track requires testing at each step of the process to verify performance and fulfillment of specifications. Individual contractors, regardless of where they fall into the schedule, will see their work tested and approved before they leave. While they are still on-site, the contractors will have the opportunity to correct any problems.

Testing passes through distinct phases during a project, beginning with factory acceptance testing (FAT) of the new automation equipment on the vendor’s assembly floor, and then to shipment, followed by a range of testing methods at the facility. These stages progress along with construction, culminating with commissioning and startup.

Resource Flexibility

Considering all the project activities that must take place in a short period of time, any company trying to carry out such a comprehensive range of management and testing must have huge resource flexibility. Over the weeks and months of a project, there will be times of relative inactivity, as well as periods when many things need to happen simultaneously—such as when a major phase is nearing completion.

Keeping things moving as quickly as possible while maintaining peak personnel efficiency demands constant adjustment of head count on-site and also specific skill sets. The right automation solutions provider will have that kind of flexibility, supplemented by tools for quickly providing test and commissioning documentation electronically. Such capabilities are critical to realizing all the possible benefits of more aggressive scheduling, while keeping costs under control.

Tools for Success

SureStart®, by MAVERICK Technologies, is a well-established startup and commissioning process designed to work in parallel with construction efforts. It tracks your project in real time with the eStart℠ electronic commissioning software application. Digital loop folders save time, and up-to-the-minute progress reports eliminate scheduling issues and unexpected delays.

When the project is completed, there can be ongoing support on-site or off through the PlantFloor24® remote monitoring solution, to ensure all gains made are preserved and expanded upon. As a leading automation solutions provider, MAVERICK Technologies performs an enormous amount of project management, startup and commissioning work—making the level of experience and technical skill at your disposal unparalleled. The investment for MAVERICK’s services is typically recovered through improved performance and the increased production benefits of earlier startup.

With more than $1 billion of automation services delivered across more than 15,000 successful projects, MAVERICK has the experience, resources and know-how to make your project an unqualified success. If you have a tough and complex project, bring it on—MAVERICK will work with you to ensure successful execution.